Dịka ihe ngwọta bụ isi n'ọhịa nke nchekwa okpomọkụ dị elu, ákwà fiberglass na teknụzụ ịgba eriri refractory na-akwalite mmezi zuru oke nke nchekwa akụrụngwa ụlọ ọrụ mmepụta ihe na arụmọrụ ike. Isiokwu a ga-enyocha njirimara arụmọrụ nke teknụzụ abụọ a, ọnọdụ ngwa na uru mmepụta ihe synergistic, iji nye ntụaka teknụzụ maka ndị ọrụ ụlọ ọrụ.

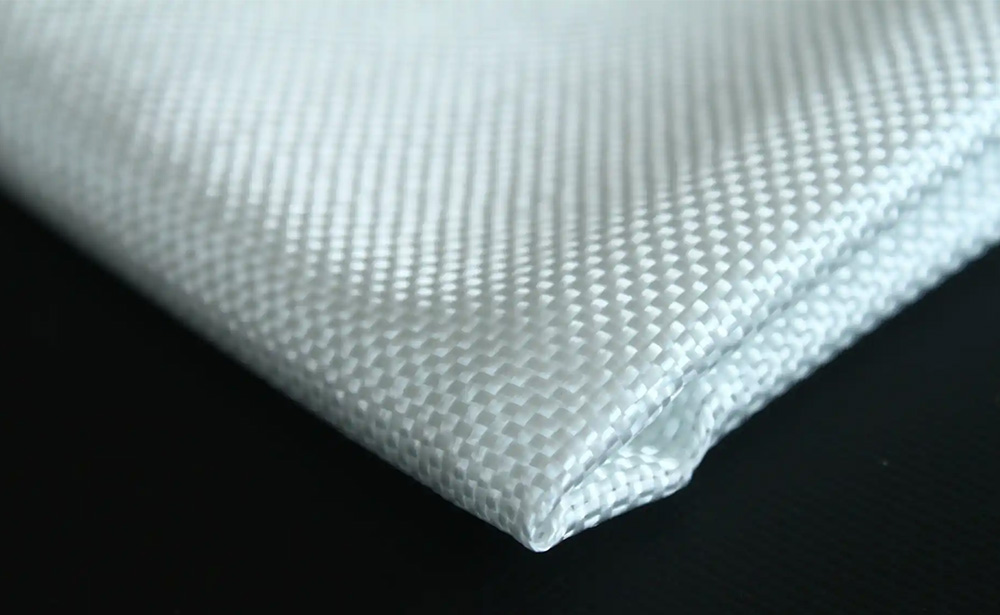

Ákwà fiberglass: ihe e ji emechi emechi maka nchekwa okpomọkụ dị elu

Ákwà fiberglass nke e ji ihe ndị na-abụghị ọla eme ihe, site na usoro pụrụ iche iji nye arụmọrụ ya dị mma, okpomọkụ dị elu, mmebi na gburugburu ebe dị mgbagwoju anya, na-aghọ ihe nchekwa kacha mma:

1. Nguzogide Okpomọkụ Dị Elu

nkịtịákwà fiberglassnwere ike iguzogide okpomọkụ dị elu karịa 500°C, ngwaahịa silica dị elu nwekwara ike iguzogide gburugburu ebe dị oke njọ karịa 1000°C. A na-ejikarị ya eme ihe n'ihe mkpuchi ọkụ ígwè, mkpuchi mbara igwe na ihe ndị ọzọ.

2. Njirimara nke na-egbochi ọkụ na mkpuchi

Ọkụ ya na-adịghị agbanwe agbanwe nwere ike iwepụ mgbasa nke ọkụ nke ọma, ọ nwekwara nnukwu mgbochi mkpuchi (10¹²-10¹⁵Ω-cm), nke dabara adaba maka nchekwa nke ngwa eletriki na mkpuchi nke ihe eletrọnịkị.

3. Mgbochi ire ere na ibu dị mfe

Nguzogide mbuze acid na alkali na-eme ka ọ bụrụ nhọrọ mbụ maka pipeline kemịkalụ na nchekwa tankị; na njupụta nke naanị 1/4 nke ígwè, ọ na-enyere aka na imewe dị mfe na ụlọ ọrụ ụgbọelu na ụgbọ ala.

Ngwa ndị a na-ahụkarị:

- Ngwa ọrụ dị elu maka okpomọkụ: mkpuchi ọkụ, mkpuchi ọkpọkọ okpomọkụ dị elu.

- Ubi ike ọhụrụ: nkwado azụ nke anyanwụ, mmụba agụba ike ifufe.

- Teknụzụ eletrọniki: Akụkụ 5G nke ọdụ isi ebili mmiri na-apụta ìhè, nchedo mkpuchi moto dị elu.

Teknụzụ Ịgbanye eriri na-adịghị mma: Mmelite mgbanwe nke mkpuchi ọkụ ụlọ ọrụ mmepụta ihe

Teknụzụ ịgba eriri na-agbanwe agbanwe site na iji usoro ihe owuwu, eriri na ihe na-ejikọ eriri agwakọtara ozugbo fesa n'elu akụrụngwa ahụ, nhazi nke usoro netwọk atọ, na-eme ka arụmọrụ nchebe dịkwuo mma nke ukwuu:

1. Uru

- Nchekwa ike na mbelata oriri: arụmọrụ mkpuchi dị mma, belata mfu okpomọkụ nke ahụ ọkụ site na 30%-50%, gbasaa ndụ nke mkpuchi ọkụ ahụ ihe karịrị ugboro abụọ.

- Ọdịdị na-agbanwe agbanwe: site na imeghari na elu dị mgbagwoju anya na nhazi ndị e ji aka rụọ, enwere ike ịgbanwe ọkpụrụkpụ ya nke ọma (10-200mm), na-edozi nsogbu nke akwa ndị na-adịghị ike nke ngwaahịa eriri ọdịnala.

- Nrụzi ngwa ngwa: na-akwado ịrụzi akụrụngwa ochie n'ịntanetị, na-ebelata oge ọrụ ma na-ebelata ọnụ ahịa mmezi.

2. Mmepụta ihe onwunwe

Site na ijikọta ihe e ji fiberglass mee na tungsten carbide, alumina na teknụzụ mkpuchi ndị ọzọ, ọ nwere ike ime ka iguzogide iyi na iguzogide okpomọkụ dị elu (na-eguzogide ihe karịrị 1200°C) ka o wee gboo mkpa siri ike nke ịgbaze ígwè, ihe ndị na-emepụta petrochemical na ihe ndị ọzọ.

Ihe Omume Ngwa:

- Mkpuchi ọkụ ụlọ ọrụ mmepụta ihe: mkpuchi okpomọkụ na nchedo refractory maka ọkụ gbawara agbawa na ọkụ ọgwụgwọ okpomọkụ.

- Ngwa ike: mkpuchi mgbochi okpomọkụ maka ụlọ ọkụ turbine gas na ọkpọkọ boiler.

- Injinia nchedo gburugburu ebe obibi: mkpuchi na-eguzogide nchara maka akụrụngwa ọgwụgwọ gas mkpofu.

Usoro ngwa synergistic: njikọta teknụzụ iji mepụta uru ọhụrụ

1. Sistemụ Nchedo Ngwakọta

N'ime tankị nchekwa petrochemical,ákwà fiberglassA na-etinye ya dị ka ihe mkpuchi okpomọkụ bụ isi, wee fesa eriri ndị na-adịghị ike iji mee ka mkpuchi ahụ dịkwuo mma, a na-emekwa ka arụmọrụ nchekwa ike zuru oke dịkwuo elu site na 40%.

2. Mmepụta Ihe Ọhụrụ Maka Ụgbọelu

Ụlọ ọrụ ụgbọelu na-eji teknụzụ ịgba mmiri eme ihe maka ịgbanwe elu nke ihe e ji ákwà fiberglass mee, nke na-eme ka oke okpomọkụ nke mkpuchi okpomọkụ nke ụlọ injin dịkwuo elu ruo 1300°C ma belata ibu site na 15%.

Ọnọdụ ụlọ ọrụ na usoro ọdịnihu

1. Mmelite ikike na teknụzụ

Sichuan Fiberglass Group na ụlọ ọrụ ndị ọzọ ga-eme ka ikike mmepụta ngwa ngwa, ikike eriri fiberglass eletrọnịkị nke tọn 30,000 na 2025, na nyocha na mmepe nke obere dielectric, mgbanwe okpomọkụ dị elu nke ngwaahịa ahụ, iji kwekọọ na ọchịchọ maka teknụzụ ịgbasa.

2. Usoro Mmepụta Akwụkwọ Ndụ Akwụkwọ Ndụ

Teknụzụ ịgbasa eriri na-adịghị mma na-ebelata ihe mkpofu ihe site na 50% na mwepụta carbon site na 20%, nke kwekọrọ na ebumnuche zuru ụwa ọnụ nke na-anaghị etinye carbon.

3. Mmepe Amamihe

N'ịjikọta ya na algọridim AI iji mee ka paramita ịgba mmiri dịkwuo mma, ọ na-ahụ maka njikwa amamihe nke ịdị n'otu na ọkpụrụkpụ nke mkpuchi, ma na-akwalite nchedo ụlọ ọrụ maka izi ezi.

Mmechi

Ngwa njikọta nkeákwà fiberglassna teknụzụ ịgba eriri na-agbanwe agbanwe na-agbanwe ókè nke nchekwa okpomọkụ dị elu nke ụlọ ọrụ mmepụta ihe. Site na mmepụta ọdịnala ruo na teknụzụ kachasị ọhụrụ, ha abụọ na-enye ngwọta dị irè ma na-adịgide adịgide maka ike, igwe ígwè, ụgbọelu na ngalaba ndị ọzọ site na arụmọrụ na imepụta ihe ọhụrụ na usoro ndị ọzọ.

Oge ozi: Maachị-17-2025