N'ime afọ abụọ gara aga, site na mgbanwe teknụzụ nke ihe nchebe okpomọkụ na-agba ọsọ maka batrị ike ọhụrụ, ndị ahịa na-achọwanye arụmọrụ mkpuchi okpomọkụ ka mma yana iguzogide ablation dị ka seramiiki - ihe dị mkpa maka iguzogide mmetụta ire ọkụ.

Dịka ọmụmaatụ, ụfọdụ ngwa chọrọ okpomọkụ iwepụ ọkụ n'ihu nke 1200°C ebe ha na-echekwa okpomọkụ n'azụ n'okpuru 300°C. N'ihe gbasara ikuku, mbelata ọkụ acetylene n'ihu na 3000°C chọrọ okpomọkụ n'azụ n'okpuru 150°C. Ihe ịma aka karịsịa bụ mmụba nke ọchịchọ maka arụmọrụ nrụgide na ụfụfụ silicone e ji seramiiki mee, nke chọrọ ma obere nrụgide na njide okpomọkụ dị mma na oke okpomọkụ. Ihe ndị a na-eweta ihe ọhụrụ achọrọ maka mkpuchi okpomọkụ maka teknụzụ seramiiki.

Ihe achọrọ maka arụmọrụ kpọmkwem (maka ntụaka naanị):

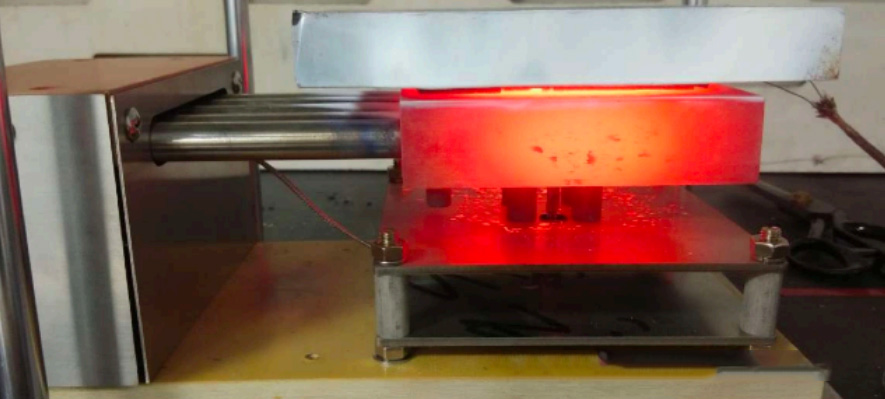

Kpoo ihe nlele ahụ ọkụ n'elu ikpo ọkụ dịka egosiri n'okpuru. Debe elu ọkụ ahụ na 600 ± 25 °C maka nkeji iri. Tinye nrụgide nke 0.8±0.05 MPa na okpomọkụ nnwale ahụ, na-ahụ na okpomọkụ azụ dị n'okpuru 200°C.

Taa, anyị na-achịkọta isi ihe ndị a maka ntụaka gị.

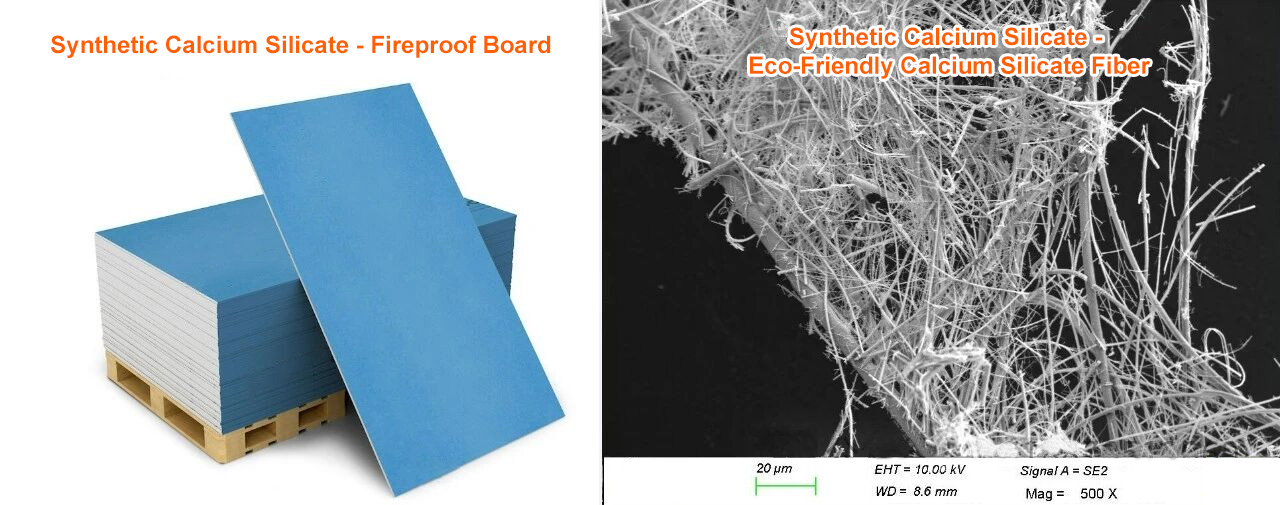

1. Calcium Silicate nke e ji sịntetik mee – Ihe mkpuchi ọkụ na-acha ọcha

Calcium silicate sịntetik dị n'ụdị abụọ: nhazi oghere/mgbara na nhazi eriri seramiiki dị ka eriri. N'agbanyeghị ọdịiche dị n'etiti ihe mejupụtara na nke ọdịdị, ha abụọ na-eje ozi dị ka ihe mkpuchi okpomọkụ dị mma nke na-eguzogide okpomọkụ dị elu.

Calcium silicate eriri sịntetik bụ ihe dị mma maka gburugburu ebe obibi na gburugburu ebe obibi.ihe nchekwa mkpuchi okpomọkụnwere oke okpomọkụ ruo 1200-1260°C. Ntụ ntụ calcium silicate nke e ji aka rụọ nke ọma nwere ike ịbụ ihe e ji eriri mee ka ọ sie ike maka mkpuchi okpomọkụ dị elu.

Ka ọ dị ugbu a, calcium silicate nke e ji ihe dị n'ime ya ma ọ bụ nke dị gburugburu nwere nnukwu ọcha, ịdị mfe nke itinye ya, nhazi nanoporous bara ụba, uru nnabata mmanụ dị elu (ruo 400 ma ọ bụ karịa), yana nnwere onwe pụọ na bọọlụ slag ma ọ bụ obere ihe ndị buru ibu. O gosipụtala na ojiji ya na mkpuchi na-eguzogide okpomọkụ dị elu na panel ndị na-anaghị agba ọkụ, na-egosi na ọ ga-ekwe omume itinye ya na ihe ndị na-eguzogide ablation nke e ji seramiiki mee iji nye mkpuchi okpomọkụ dị elu.

Ngwa ndị ọzọ gụnyere: ihe mgbakwunye mmiri mmiri ntụ ntụ, ihe mkpuchi ntụ ntụ na-egbochi okpomọkụ dị elu, ihe ndị na-ebu ihe na-esi ísì ụtọ, ihe ndị na-egbochi ntapụ mmiri, ihe ndị na-akpata esemokwu pad brek, rọba silicone dị ala na mmanụ silicone nke na-emebi onwe ya, ihe na-ejupụta akwụkwọ, wdg.

2. Igwe Magnesium Aluminom Silicate nke dị larịị- Mkpuchi Okpomọkụ na Nguzogide Okpomọkụ Dị Elu

Ihe a na-akpọ silicate mineral a chọrọ ka a na-eme ka ọ dị ọkụ nke ọma, ọ na-enwekwa ike iguzogide okpomọkụ ruo 1200°C. Ọ bụ magnesium aluminum silicate ka e ji mee ya, ọ nwere ihe owuwu nwere oghere dị larịị nke na-enye ike njikọ dị elu, ezigbo ike iguzogide mmiri, ogologo oge iguzogide ya, na ọnụ ahịa dị elu.

Ọrụ ya bụ isi gụnyere mkpuchi okpomọkụ dị elu, mbelata njupụta, mmụba nke refractory, na mmezi nke iguzogide ablation na mkpuchi okpomọkụ maka oyi akwa carbon na casings. Ngwa ndị a gụnyere ihe mkpuchi seramiiki, mkpuchi ọkụ dị elu, ihe mkpuchi refractory, na ihe mkpuchi okpomọkụ na-eguzogide ablation.

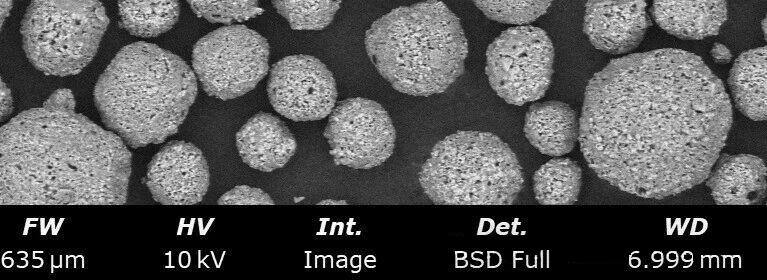

3. Microspheres seramiiki - Nguzogide Okpomọkụ Dị Elu, Mkpuchi Okpomọkụ, Ike Mkpakọ

Ihe ndị dị n'ime iko oghere bụ ihe ndị na-egbochi okpomọkụ nke ọma, mana ha anaghị eguzogide okpomọkụ nke ọma. Ebe ha na-eme ka ha dị nro na-adịkarị site na 650-800°C, ebe okpomọkụ ha na-agbaze na 1200-1300°C. Nke a na-ebelata ojiji ha na ọnọdụ mkpuchi okpomọkụ dị ala. N'okpuru ọnọdụ okpomọkụ dị elu dịka seramiiki na iguzogide ablation, ha na-aghọ ndị na-adịghị arụ ọrụ nke ọma.

Ihe ndị dị n'ime seramiiki anyị dị n'oghere na-edozi nsogbu a. Ha bụ aluminosilicate, ha na-enye ike iguzogide okpomọkụ dị elu, ike mgbochi okpomọkụ dị egwu, ike mgbaji dị elu, na ike mgbaji ọkpụkpụ dị elu. Ngwa ndị a gụnyere ihe mgbakwunye seramiiki silicone, ihe mkpuchi na-adịghị mma, ihe mgbakwunye okpomọkụ dị elu maka resin organic, na ihe mgbakwunye roba na-eguzogide okpomọkụ dị elu. Akụkụ ndị dị mkpa gụnyere ikuku, nchọpụta miri emi n'oké osimiri, ihe mejupụtara, mkpuchi, mkpuchi na-adịghị mma, ụlọ ọrụ mmanụ ala, na ihe mkpuchi.

Nke a bụ obere ntụ ntụ okirikiri nwere oghere na-anaghị ekpo ọkụ nke na-adịghị ekpo ọkụ nke ọma, ọ dịkwa mfe itinye ya (n'adịghị ka obere ihe mkpuchi iko nwere oghere, nke chọrọ ka a gbasaa ya tupu oge eruo ma ọ bụ gbanwee ya maka mgbakwunye kwesịrị ekwesị) ma na-egosipụtakwa ezigbo iguzogide mgbawa. Ihe pụrụ iche ya bụ na ọ bụ ihe mepere emepe nke na-anaghị ese n'elu mmiri, nke na-eme ka ọ dị mfe ịka mma ma daa.

Ọzọkwa, a na-ekwu maka obere okwu gbasarantụ ntụ aerogel—ihe e ji silica mee nke e ji ihe na-egbochi mmiri. A maara Aerogel nke ọma dị ka ihe na-egbochi okpomọkụ dị mma, nke dị na ụdị hydrophobic/hydrophilic. Nke a na-enye ohere ịhọrọ ụzọ ọgwụgwọ kwesịrị ekwesị dabere na ihe ndị e ji resin mee, na-edozi nsogbu nke ntụ ntụ aerogel nke mgbasa dị oke mfe ma na-eme ka ọ gbazee nke ọma. E nwekwara ihe e ji mmiri mee nke e ji aerogel mee maka itinye ya n'ime sistemụ mmiri.

Njirimara pụrụ iche nke mkpuchi okpomọkụ nke ntụ ntụ aerogel na-eme ka ojiji ya dị na: – Ihe ndị na-ebu ihe mgbakwunye rọba na plastik – Ihe mkpuchi okpomọkụ maka batrị ike ọhụrụ – Mkpuchi mkpuchi ụlọ – Eriri ákwà mkpuchi okpomọkụ – Ogwe mkpuchi ụlọ – Mkpuchi mkpuchi okpomọkụ na-anaghị agba ọkụ – Ihe mgbakwụnye mkpuchi okpomọkụ.

Oge ozi: Sep-22-2025